Sodium bromide for petroleum industry

200 INR/Kilograms

Product Details:

- Molecular Weight 102.89 g/mol

- Poisonous Non-Poisonous

- CAS No 7647-15-6

- Shelf Life 24 months

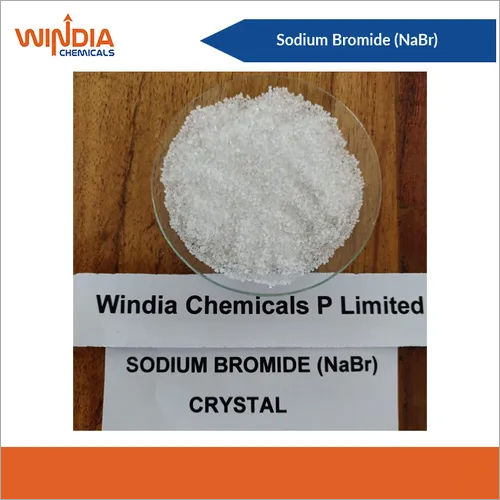

- Appearance White crystalline powder

- HS Code 28275100

- Storage Store in a cool, dry, well-ventilated area, away from moisture

- Click to View more

X

Sodium bromide for petroleum industry Price And Quantity

- 300.00 - 400.00 INR/Kilograms

- 25 Kilograms

- 200 INR/Kilograms

- Available on request

- Not classified as hazardous under GHS

- Compatible with most completion and workover fluids

- 5.0 - 8.0 (5% solution)

- Non-toxic at recommended uses

- 231-599-9

- 0.005%

- 0.5%

- 0.8 - 1.1 g/cm

- 25 kg/50 kg HDPE bags with inner liner or as required

- Available as fine powder and granules

- 0.002%

- 0.5%

Sodium bromide for petroleum industry Product Specifications

- NaBr

- Used to increase density of fluids, control formation pressure, and prevent blowouts

- Powder or Granules

- 231-599-9

- 755C

- 3.21 Gram per cubic centimeter(g/cm3)

- Sodium bromide (NaBr)

- Br-Na+

- Store in a cool, dry, well-ventilated area, away from moisture

- White crystalline powder

- Highly soluble in water

- 28275100

- Saline

- >99%

- High purity, Water soluble, Non-volatile, Stable under normal conditions

- Odorless

- Industrial Grade

- 7 (1% solution)

- 24 months

- 7647-15-6

- Crystalline

- 102.89 g/mol

- Oil drilling, Workover fluids, Completion fluids in petroleum industry

- Non-Poisonous

- Inorganic Salt

- Available on request

- Not classified as hazardous under GHS

- Compatible with most completion and workover fluids

- 5.0 - 8.0 (5% solution)

- Non-toxic at recommended uses

- 231-599-9

- 0.005%

- 0.5%

- 0.8 - 1.1 g/cm

- 25 kg/50 kg HDPE bags with inner liner or as required

- Available as fine powder and granules

- 0.002%

- 0.5%

Sodium bromide for petroleum industry Trade Information

- 100000 Kilograms Per Month

- 2-3 Week

Product Description

We provide Sodium Bromide for Petroleum Industry.

For the miscellaneous requirements of our customers, we are engaged in offering a quality range of Sodium Bromide for Petroleum Industry. These products are exclusively formulated and are sourced from reliable vendors of the industry that ensure their durability and purity. All these products are safe to use and are widely appreciated by our valued customers.

Specifications of the product:

- Come in white crystalline form

- Appearance of 10% aqueous solution - Clear and Colorless

- Assay (on dry basis) = >99.5%

- pH of 5% Solution = 6-9

- Moisture by wt. = <0.5%

- Iron % (Fe) = O.001

- Heavy metals (as Pb %) = <0.001

- Insoluble matter % by weight = <0.003

Engineered for Oil Drilling Needs

Sodium bromide is specifically formulated to address the complex requirements of the petroleum industry. Its high purity and excellent solubility allow it to serve as a reliable brine additive in drilling, completion, and workover operations. This product helps manage wellbore pressures and ensures the safety and efficiency of various oilfield tasks, all while maintaining chemical stability during use.

Quality and Safety are Paramount

Each batch of sodium bromide undergoes strict quality control to meet international specifications, ensuring minimal impurities like chloride, iron, and free alkali. It is classified as non-toxic and non-poisonous at recommended concentrations, and is packaged securely for global export. Its risk profile is low, as it is not classified as hazardous under the GHS guidelines, supporting safe storage and handling.

FAQs of Sodium bromide for petroleum industry:

Q: How is sodium bromide used in the petroleum industry?

A: Sodium bromide is added to drilling, workover, and completion fluids to increase their density, allowing operators to control subsurface formation pressures and prevent blowouts during drilling and maintenance activities.Q: What benefits does sodium bromide offer for oilfield applications?

A: It provides high purity and water solubility, enabling precise density adjustment, compatibility with most fluids, and stable performance under extreme conditions, all critical for effective pressure control and operational safety.Q: When should sodium bromide be incorporated into drilling operations?

A: Sodium bromide is typically introduced during drilling, workover, or completion phases when fluid density needs to be controlled to manage well pressure or stabilize the formation.Q: Where should sodium bromide be stored for best shelf life?

A: Store sodium bromide in a cool, dry, and well-ventilated area, away from moisture. Proper storage conditions maintain product integrity and extend its shelf life up to 24 months.Q: What is the process for preparing sodium bromide brine for completion fluids?

A: Dissolve the required quantity of sodium bromide (powder or granules) in water while monitoring the pH and density. Adjust liquid proportions to meet project-specific requirements as indicated on the Certificate of Analysis.Q: How does sodium bromide contribute to safer oil drilling operations?

A: By raising fluid density, sodium bromide assists in balancing formation pressures, reducing the risk of well kicks or blowouts, and supporting safer, more predictable drilling and completion activities.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email